When we think of synthetic biology, we often think of synthetic DNA. However, the purpose of the DNA is often to make protein. Today we can order DNA overnight for cheap, but producing protein takes at least two weeks of lab work with various instruments and techniques. Liberum aims to free researchers from the tedious task of turning DNA into protein and make experiments faster and cheaper. I chatted with Liberum’s CEO, Aidan Tinafar.

How important is protein for biological research and production?

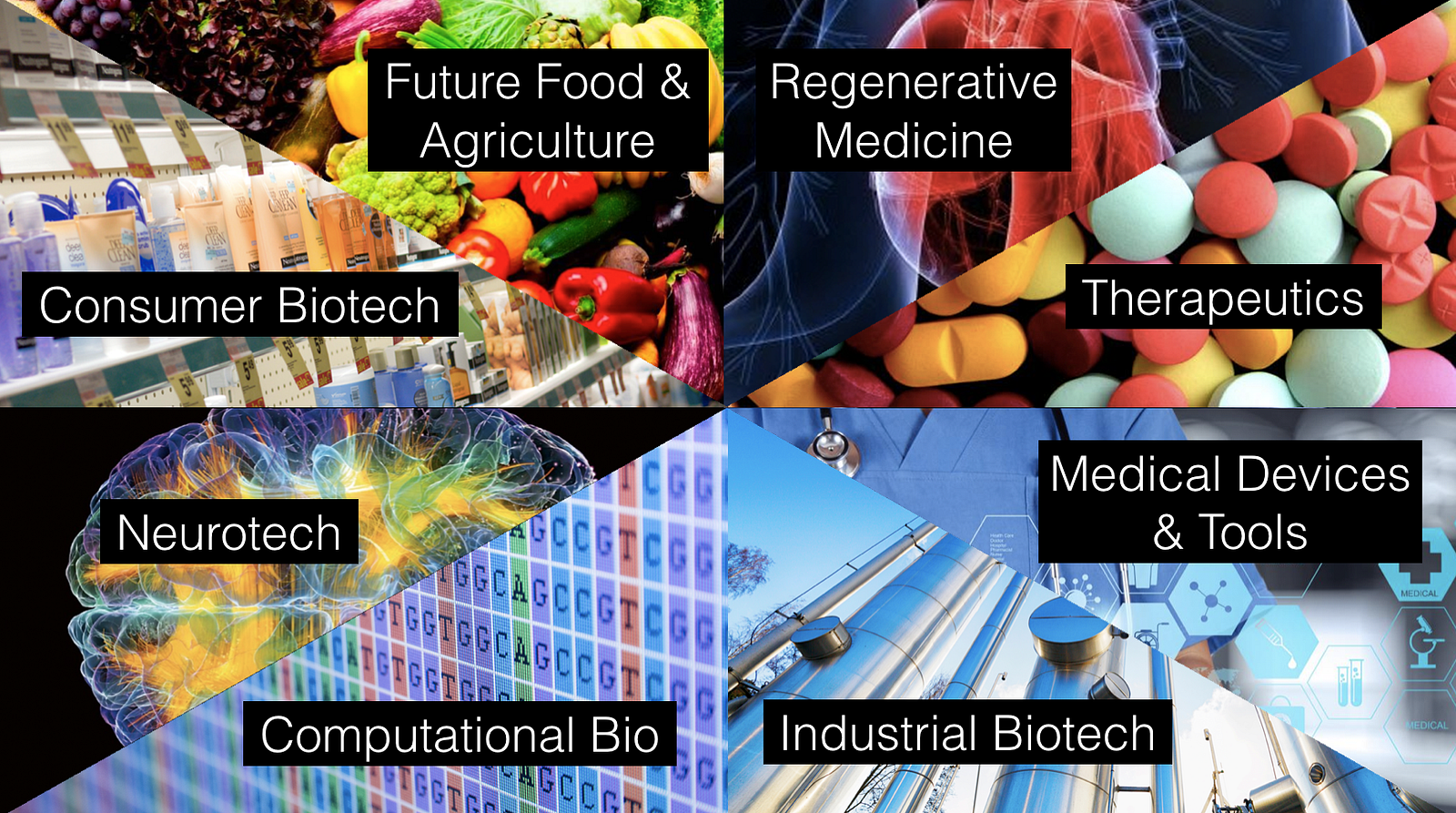

When most people hear the word protein, they immediately think of food. Proteins are far more than food. They are used as therapeutics, industrial catalysts, biomedical research tools, materials for manufacturing and additives in consumer goods just to name a few. Insulin is a protein. Chymosin, the enzyme that enables cheesemaking is a protein. Silk is two proteins combined.

Imagine if you could come up with a type of material that you could design with vastly diverse physical and chemical properties for a whole host of applications. Ideally, you would want this material to have three properties. First, you would want to be able to make the material from a small set of inputs that are readily available. Second, you would want to be able to control the properties of the material in a tunable or programmable fashion. And third, you would want the production process to be sustainable and capable of being integrated into pre-existing environmentally-friendly modes of production. Protein is that type of material.

Proteins are strings of building blocks called amino acids that are folded and held together such that they enable certain functions. Combinatorial combinations of 20 amino acids give rise to all the breathtaking diversity we see in nature. The type and order of amino acids are generally encoded within the DNA of an organism. A single cell such as an E. coli bacterium requires a couple thousand different proteins to carry out its biological activity. These proteins can act individually or in concert as networks.

One way to take advantage of proteins is to piggyback on an existing living organism. For example, we can use yeast to make beer without having to deal with its proteins on a granular level. We can also benefit from extracts, secretions or purified proteins from organisms found in nature.

In the 70s, we began gaining a grasp on being able to mix and match these wild-type proteins between organisms through somatic fusions and recombinant technologies. During the same decade, chemical synthesis of a complete gene was demonstrated for the first time. Shortly after, in the 80s, polymerase chain reaction (PCR) was invented allowing us to make billions of identical copies of these chemically derived sequences. Together, these technologies enable us to go from a digital DNA sequence stored on a computer to a designer protein within weeks. At Liberum, we significantly speed up this process, so that we can create better products faster.

These breakthroughs have already brought about the synthetic biology revolution with a total market size worth hundreds of billions of dollars and rapidly growing. For example, the size of the recombinant therapeutics market alone is now over 100 billion dollars. There are two factors that have hidden this revolution in plain sight. Firstly, cultural taboos surrounding genetically modified organisms (GMOs) have incentivized many to categorize these products as natural rather than engineered ones. More importantly, the wide range of applications of these technologies make the market appear highly fragmented. End products include anything from extracts and purified proteins to small molecules, cell lines and other goods and services that use these as intermediates. While apps of the internet revolution came to most through their screens, proteins that lead the synthetic biology revolution touch people’s lives in so many ways that make them hard to categorize as a single class. Massive shifts are often harder to observe.

What are the bottlenecks in creating protein today and how is your technology solving those bottlenecks?

Making protein using biology is hard. For every idea, for every iteration, you have to re-engineer the genetics of living cells, grow them, break them open and purify. This process is very hands-on. You need to keep coming back to it over a week or two. The process also requires expertise and expensive equipment that take up a lot of space. Even if you outsource the work to a contract research organization, you are still bound by similar timelines, plus the duration of shipping. Liberum speeds up and automates the protein manufacturing process in a miniaturized device without having the need to re-engineer any living cells. We do it all in a cell-free system that contains the same powerful enzymatic machinery used by cells.

Now you may wonder, why can we not chemically synthesize these proteins; what is so special about using biology to accomplish protein manufacturing? The problem with chemical synthesis of proteins is really two-fold. First, the error rate for state-of-the-art chemical amino acid incorporation hovers around 1%. This means that for an average bacterial protein of 320 amino acids in length, only about 4% of the final mixture would contain the correct sequence. More importantly, proper folding of amino acid chains into functioning proteins tends to be trickier in chemical systems. A system that more closely resembles biological conditions, such as a cell-free protein expression system, can avoid these problems.

Technical challenges of making proteins aside, there is a deeper conceptual issue at play. We can certainly make a protein of a specific function starting from a working DNA blueprint, but designing that blueprint is far from trivial. While rational and modular protein designs can be highly informative, they are rarely strictly prescriptive. One often needs to screen sizable libraries of designs to optimize for a specific function. Even if we take wild-type sequences from organisms in nature, there is still room for validation and screening of homologues. Unless and until we have computational means that can predictably design for functionality in silico, protein prototyping remains an indispensable tool for protein engineering.

How might your company change the way we produce protein?

We want to enable protein manufacturing at small scale with minimal time and capital investment on the part of our customers. The key insight for our business model is that we have separated the fermentation process from the act of protein production. This allows us to operate as a utility company that delivers protein production capacity to our clients on-demand. Our device and cartridges are merely the last mile. The infrastructure we build to enable this capacity is where much of the value we provide will be generated.

Once our customers have ordered and amplified their template DNA, they can simply place it inside one of our cartridges and produce their desired protein with a push of a button. Having the capacity in their own labs will allow them to optimize the desired conditions. It also provides control and rapid turnaround to enable more bright ideas to see the light of day.

What lessons have you learned transitioning from scientist to entrepreneur during the IndieBio program?

Put the customer first. Science is just the tool we use to serve our customers and the community at large. The value of our company is a function of the value we create for our customers and other stakeholders in the community.

What does the next year look like for Liberum?

Rapid iteration cycles to loop in customer feedback has been in our company’s DNA from the very early days. Our goal over the next year is to build our infrastructure such that we can bring the power of cell-free protein expression to thousands of labs around the world at very affordable prices. We will continue to build upon enhancing user experience through further iterations of the device and cartridges. Our goal is to wrap up alpha and beta testing as soon as possible so that we can launch our product within the next year.